Business Project of Apple

Apple Inc. is one of the most valuable technology companies in the world, known for combining sleek design, powerful performance, and a tightly integrated ecosystem across its products. The iPhone remains the company’s most important revenue driver, consistently accounting for around half of Apple’s total sales in recent years.

Each annual launch is not only a major commercial event but also a cornerstone of Apple’s brand strategy, shaping customer loyalty and market perception.

In 2025, Apple faces an urgent challenge ahead of the planned release of the iPhone 17. A shortage of low-thermal-expansion-coefficient (low-CTE) fibreglass cloth, a specialised material used in the device’s heat management system, threatens to disrupt production.

This material is critical for regulating internal temperatures, protecting battery life, and ensuring the phone’s long-term performance. Grace Fabric Technology, Apple’s main supplier, is currently unable to meet demand, and with only one other manufacturer able to produce the component at scale, Apple’s sourcing options are severely limited. With the launch less than five months away, the risk of delays or restricted availability is significant.

The issue goes beyond one missing material. It highlights the fragility of even the most sophisticated supply chains and the strategic importance of resilience in global technology manufacturing. Tim Cook has emphasised in past interviews that supply chain excellence is a core part of Apple’s competitive advantage, enabling the company to deliver complex, high-quality products at scale. Disruptions like this one threaten not only sales but also Apple’s hard-earned reputation for reliability and timely delivery.

This report will first examine the nature and implications of the shortage, then assess its impact on key stakeholders. It will analyse secondary data through recognised business frameworks, before presenting recommendations to help Apple address the immediate problem and strengthen its long-term supply chain strategy.

Read more: Business Project of Apple Inc.

Challenge and Issues the Client is Facing

Apple’s upcoming iPhone 17 launch faces a serious threat from a shortage of a key material: low thermal expansion coefficient (low-CTE) fibreglass cloth. This ultra-thin, high-performance material plays a crucial role in the phone’s heat management system, helping to keep internal temperatures stable, extend battery life, and preserve the device’s overall longevity.

The supply gap stems from Apple’s heavy reliance on one main supplier, Grace Fabric Technology, which is currently unable to meet demand. With only one manufacturer in the world that can produce this component at the necessary scale, this leaves Apple with extremely limited sourcing options.

The urgency of the problem is heightened by the tight product cycle. With less than five months before the expected September 2025 launch, Apple’s production schedule leaves little room for delays. Any slowdown in securing the fibreglass cloth could force last-minute manufacturing changes or a reduction in the number of units available at launch.

In addition to risking lost sales, limited supply could drive customers toward competing devices or second-hand iPhones, eroding the momentum of one of Apple’s most important annual events.

This shortage is not happening in isolation; it reflects broader patterns of post-pandemic supply chain fragility. The COVID-19 pandemic exposed vulnerabilities in global manufacturing, from factory shutdowns to transport bottlenecks.

While many industries have since recovered, high-tech manufacturing remains sensitive to disruptions due to its dependence on precision components and just-in-time production. In Apple’s case, the high level of specialisation in the fibreglass cloth means there is little flexibility when suppliers face unexpected production limits.

Geopolitical factors further complicate the picture. Global tensions, particularly those affecting trade between the United States and key manufacturing regions in Asia, can lead to sudden export restrictions, tariffs, or political barriers.

Such risks are especially pressing for companies like Apple, which sources many components from suppliers with operations in regions where political and economic conditions can shift quickly.

An important emerging trend in the industry is the growing dependence on highly specialised materials and components. As smartphones pack in more advanced features, such as enhanced cooling for high-performance processors, manufacturers increasingly rely on niche suppliers with unique technical capabilities.

This creates a paradox: innovation improves product performance but also narrows the pool of potential suppliers, increasing vulnerability to shortages. Apple’s reliance on Grace Fabric Technology for low-CTE fibreglass is a prime example.

Competitors are responding to similar risks with strategies such as dual-sourcing, vertical integration, or investment in supplier capacity. For instance, Huawei has formed long-term contracts or even taken equity stakes in suppliers to secure access to critical components.

These moves reflect a growing recognition that supply chain resilience is no longer a back-office concern but a central pillar of competitive strategy in the technology sector.

Purpose of the Report:

This report aims to evaluate the impact of a critical low-CTE fibreglass cloth shortage on Apple’s upcoming iPhone 17 launch and to provide strategic recommendations that strengthen the company’s supply chain resilience.

This shortage poses a direct risk to the timely release of Apple’s flagship product, which generated approximately 51% of the company’s $394 billion revenue in 2024. Given the iPhone’s central role in sustaining Apple’s market leadership and brand loyalty, any disruption to its production could have significant financial and reputational consequences.

The focus of this investigation is justified by the high dependency on a single supplier for a specialised component and the limited availability of alternatives. This situation reflects broader challenges in the technology sector, where innovation often increases reliance on niche suppliers, amplifying supply chain vulnerabilities.

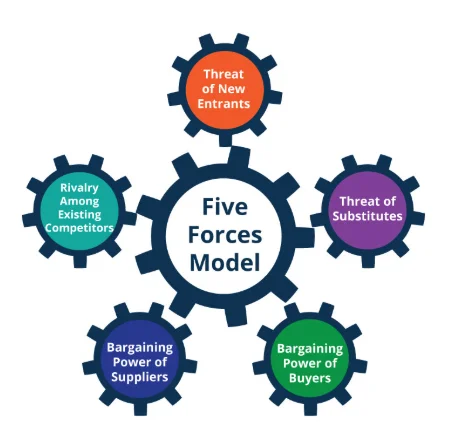

To assess the issue thoroughly, this report applies PESTLE analysis to explore external factors influencing supply stability, Porter’s Five Forces to evaluate supplier power and market competition, SWOT analysis to highlight Apple’s internal strengths and weaknesses in managing the risk, and Mendelow’s Matrix to map stakeholder priorities. These frameworks will guide a structured evaluation, ensuring that recommendations are both evidence-based and strategically valuable for Apple’s long-term resilience.

Stakeholder Analysis

Apple’s response to the low-CTE fibreglass cloth shortage will be shaped by a complex network of internal and external stakeholders. These groups vary in their level of influence and interest, and misalignment between them can heighten operational and reputational risks. Using Mendelow’s Matrix, stakeholders are mapped according to their power to influence the outcome and their level of interest in the iPhone 17 launch.

Internal Stakeholders:

Apple Executives:

Senior leadership, including CEO Tim Cook and operations heads, holds both decision-making authority and a direct interest in resolving the shortage. Their priorities are safeguarding launch timelines, protecting revenue streams, and maintaining investor confidence.

Given Cook’s operations background, the expectation for decisive action is high. Failure to deliver could undermine perceptions of Apple’s legendary supply chain precision.

Engineering and Product Teams:

Engineering teams are responsible for integrating the fibreglass cloth into the iPhone’s thermal management system. Their interest is high; design or material changes could compromise product performance, but they have little control over supplier contracts. This dependence creates operational bottlenecks if executives fail to secure adequate materials in time.

External Stakeholders:

Grace Fabric Technology:

As the main supplier of low-CTE fibreglass, Grace holds disproportionate bargaining power. However, its interest is primarily in maintaining long-term commercial relations rather than the specific iPhone 17 launch date. This creates potential misalignment; Apple’s urgency may not translate into equal urgency for Grace, especially if it has other major customers.

Foxconn:

Foxconn, Apple’s largest assembler, has a vested interest in a smooth production flow. While it cannot produce the fibreglass itself, delays in receiving the material will disrupt assembly schedules, workforce planning, and factory efficiency. This could strain Apple–Foxconn relations, especially given recent scrutiny over labour practices in Foxconn facilities.

Customers:

While individual consumers lack direct bargaining power, their collective influence is significant through purchase decisions and brand advocacy. A delayed or limited iPhone 17 launch could frustrate loyal customers loyal customers, push them toward competitors, or diminish excitement around the product cycle. Social media amplifies this risk; as negative sentiment can spread rapidly.

Shareholders and Institutional Investors:

Investors closely monitor Apple’s product launches as indicators of revenue growth. Any delay can trigger short-term stock volatility and raise concerns over operational resilience. While their interest is strong, their influence is indirect, exercised through market reactions and engagement with Apple’s investor relations team.

Impact Evaluation:

- Financial: Shareholders face potential earnings volatility; suppliers could see revenue gains if Apple pays premium prices for expedited production.

- Operational: Manufacturing partners like Foxconn may incur inefficiencies; engineering teams risk rushed design adjustments.

- Reputational: Customers may lose confidence in Apple’s ability to deliver on time, and competitors could capitalise on the delay.

The stakeholders with the greatest leverage over the iPhone 17 launch are Apple’s senior executives and Grace Fabric Technology. Their decisions, how quickly they act, what compromises they accept, and how they negotiate supplier terms, will determine whether the shortage becomes a minor setback or a major strategic failure. Balancing these relationships while managing investor expectations and customer loyalty will be the defining challenge of Apple’s response.

Evaluation & Analysis

External Factors Influencing the Supply Chain Challenge:

A PESTLE analysis helps to expose how external factors deepen the vulnerability of Apple’s supply chain, especially regarding the critical low‑CTE fibreglass cloth shortage. Below is a visual mapping table, immediately followed by a tightly focused discussion under each PESTLE dimension.

Table 1 PESTLE Analysis

| PESTLE Factor | External Influence | Impact on iPhone 17 Shortage & Apple’s Strategy |

| Political | U.S.-China trade tensions, tariffs, and export controls | Risk of sudden cost spikes or supply blockage from Grace Fabric Tech |

| Economic | Rising component costs, inflation, and currency volatility | Shrinking margins, forced pass-through pricing, or compromised profitability |

| Social | Expectation of punctual premium product launches | Reputation damage and customer disappointment if supply falters |

| Technological | Advances in alternative materials / thermal tech | No viable backup, Apple’s R&D hasn’t delivered timely substitutes |

| Legal | Export/import restrictions and strict IP frameworks | Limited room for a rapid supplier switch or workaround under an emergency |

| Environmental | Demand for green sourcing and transparency | Potential backlash if the fibreglass supply is viewed as unsustainable or opaque |

Political:

Trade tensions between the U.S. and China continue to intensify, with escalating tariffs and export restrictions that directly affect technology supply chains. Apple’s dependence on Grace Fabric Technology, a Chinese supplier, for the low‑CTE material exposes it to sudden cost surges or blockages.

Apple appears to lack the flexibility of “China Plus One” strategies adopted by others. This exposes a dangerous blind spot in Apple’s geopolitical risk contingency.

Economic:

Global inflation and cost pressures are pushing up prices for key components, while currency swings create contract instability. Many suppliers now demand rushed premiums, pressures Apple seems unwilling to openly acknowledge, risking critical profit erosion.

Apple’s lean cost structures lack slack, leaving the firm vulnerable if it needs to absorb rising component prices or pass costs to consumers, which could harm brand value.

Social:

Consumers expect Apple’s flagship iPhones to launch smoothly each year, maintaining a premium experience and exclusivity. A disrupted release risks damaging cultivated brand loyalty. The current supply gap threatens this trust, yet Apple’s marketing plans remain locked in, suggesting insufficient scenario planning for reputational fall‑back paths.

Technological:

While materials science is advancing, especially in thermal management and composites, no alternative to low‑CTE fibreglass appears ready for Apple’s high standards. This highlights a strategic failure: despite heavy R&D spending, Apple hasn’t developed or qualified fallback materials fast enough to mitigate a single-source risk.

Legal:

Export controls complicate how Apple moves materials or design IP across borders. Grace’s location in China poses licensing challenges; tight IP frameworks may further slow Apple from onboarding alternate suppliers quickly. Such legal rigidity suggests Apple prioritised proprietary control over agile response in crisis conditions.

Environmental:

Apple’s growing sustainability commitments mean its supply chain must meet ethical and environmental standards. The fibreglass shortage raises questions: is the supply both scalable and compliant? Apple’s silence on greener alternatives underlines an oversight in its strategic resilience planning.

Competitive Pressures in the Smartphone Supply Chain:

Porter’s Five Forces framework provides a lens for assessing the competitive pressures shaping Apple’s supply chain vulnerabilities. In the case of the low-CTE fibreglass shortage, each force reveals structural weaknesses in Apple’s approach, many of which competitors have already moved to mitigate.

Supplier Power:

Supplier power measures the ability of suppliers to influence price, quality, and availability. Apple’s dependence on Grace Fabric Technology as its primary source gives the supplier disproportionate leverage.

Scarcity allows Grace to dictate terms on lead times and pricing, knowing Apple lacks alternative sources that meet its technical standards.

Competitors such as Samsung have reduced this risk by developing dual-sourcing agreements and partial vertical integration. Apple’s failure to adopt similar diversification strategies leaves it exposed to both market-driven and geopolitical supply shocks.

Buyer Power:

Buyer power refers to the influence customers (buyers) have over suppliers. Apple’s size and consistent order volumes typically give it a dominant negotiating position. However, in this case, scarcity undermines that leverage.

When a component is irreplaceable in the short term, suppliers have little incentive to concede on price or delivery schedules.

Apple’s bargaining position is further weakened by its brand’s dependence on the punctual annual release of flagship products. Delays risk eroding market confidence, giving suppliers indirect leverage over Apple’s strategic timetable.

Threat of Substitutes:

At the component level, the threat of substitution is negligible; few materials can match low-CTE fibreglass for thermal stability and durability in smartphone design. However, at the product level, substitution risk is substantial.

If the iPhone 17 launch slips, consumers could switch to rival devices from Samsung, Huawei, or Google Pixel, particularly in competitive Asian markets where loyalty is weaker. This makes launch punctuality a critical competitive battleground.

Threat of New Entrants:

High capital requirements, specialised manufacturing expertise, and strict intellectual property barriers make entry into the high-spec fibreglass market highly unlikely. While this protects existing suppliers from disruption, it also locks Apple into its current network.

Low entry threat benefits incumbents far more than buyers, removing competitive pressure that could otherwise drive innovation, capacity expansion, or price moderation.

Industry Rivalry:

The global smartphone market is characterised by aggressive competition over market share, innovation cycles, and supply chain efficiency. Samsung have invested heavily in supply chain resilience, including onshore component manufacturing and diversified supplier portfolios.

Apple’s current crisis underscores a relative strategic lag in supply chain fortification. If rivals can maintain their product release schedules during Apple’s disruption, the competitive damage will extend beyond one product cycle.

Apple’s Strategic Position in Managing the Shortage:

SWOT analysis offers a focused way to assess Apple’s internal strengths and weaknesses against the external opportunities and threats identified in the PESTLE and Porter’s Five Forces. In the low-CTE fibreglass shortage, this lens exposes both the leverage Apple could exploit and the blind spots that could prove costly.

Table 2 SWOT Analysis

| Strengths | Weaknesses |

| Exceptional brand loyalty and premium market position.Large cash reserves ($60bn+ in 2024) enabling rapid investment. Global logistics expertise and established distribution network. | Heavy reliance on a single supplier for critical material.Limited short-term sourcing flexibility.Slow diversification despite repeated supply shocks. |

| Opportunities | Threats |

| Vertical integration to cut supplier dependency.Long-term multi-region supplier partnerships.R&D into alternative materials for resilience. | Delayed iPhone 17 launch, risking share loss.Investor confidence dips and share price volatility.Negative media framing as poor foresight. |

Strengths:

Apple’s brand loyalty enables pricing power and customer retention, potentially cushioning short-term disruption. Substantial cash reserves could fund urgent supplier agreements or material R&D. A mature logistics network supports rapid global rollout if production resumes.

These assets are not permanent shields. Brand loyalty can erode with repeated delays, as seen in Samsung’s 2016 Note 7 fallout. Capital is ineffective without decisive, fast-track execution, and logistics strength does not solve raw material scarcity.

Weaknesses:

The most acute weakness is single-source dependency, a textbook supply chain vulnerability. Limited flexibility means production bottlenecks cannot be resolved quickly. Apple’s slow pace in material diversification since the COVID-era disruptions suggests structural complacency.

Opportunities:

Vertical integration could eventually stabilise supply, echoing Tesla’s in-house battery production. Multi-region supplier partnerships could add resilience, but would require cultural change in supplier management. R&D into alternatives offers long-term insurance but cannot rescue the iPhone 17 timeline.

All opportunities are medium-to-long-term plays, unrealistic as immediate fixes to the current crisis.

Threats:

The immediate danger is a delayed launch, giving rivals like Samsung and Huawei a competitive window. Share price volatility from supply disruption is well-documented in the tech sector. Media framing this as strategic negligence could compound reputational harm.

Apple’s financial and brand strengths give it tools, but its operational weaknesses directly amplify its threats. The over-reliance on a single supplier links directly to the highest-impact risks: launch delays, investor unease, and reputational damage. Without urgent structural reform, opportunities will remain hypothetical while threats materialise in real time.

Impact Evaluation:

A data-driven view tests Apple’s narrative against hard numbers and exposes where certainty is weakest. It also shows why a single-point failure in materials can scale into a strategic shock.

iPhone remains Apple’s dominant cash engine; FY2024 filings show about half of total sales come from iPhone. A one-month slip in the iPhone 17 ramp would likely defer a material share of launch-quarter revenue; modelling a conservative shift of expected first-quarter iPhone sales implies multi-billion deferrals, with knock-on margin risk from mitigation costs.

Industry lead-time data confirm that component supply remains volatile: chip lead times fell from 26–27 weeks in 2022 but stayed well above pre-COVID norms (≈12–15 weeks), signalling fragile buffers and long recovery tails. For a just-in-time iPhone build, even small upstream slippage cascades into final assembly and channel fill. Apple’s tight cadence magnifies any delay at a single specialist supplier.

The ultra-thin, low-CTE fibreglass cloth used for PCB thermal stability is supplied by a handful of East Asian specialists; Apple’s primary source is Grace Fabric Technology, widely described as the largest supplier and one of only two able to mass-produce to spec. Concentration raises allocation and pricing power against Apple exactly when it most needs volume.

Competitors have stronger structural hedges. Samsung is vertically integrated across displays, semiconductors and materials through SDC/DS divisions and affiliates, enabling multi-sourcing and faster reallocation in shocks; its filings and investor decks emphasise this breadth. Apple’s diversification drive is real but slower and less integrated at the component level, leaving it exposed when a niche input tightens.

Limitations of the Secondary Data Evaluation:

While the preceding analysis is grounded in multiple reputable secondary sources, there are important methodological constraints that reduce the certainty of its conclusions and the precision of its forecasts. These limitations must be recognised to avoid overconfidence in the findings and to ensure that subsequent recommendations are proportionate to the evidence base.

Much of the supplier market concentration and lead-time data predates Q3 2025, meaning it may not reflect recent capacity expansions, contract renegotiations, or political developments. In niche, high-spec materials markets, a single plant upgrade or policy shift can materially alter supply dynamics within months, making historical figures a potentially unreliable predictor of near-term realities.

Apple’s own filings and press releases are curated to protect investor confidence and may under-report operational fragilities. Similarly, industry media and analyst commentary can skew towards sensational or commercially appealing narratives, particularly when reporting on “bottleneck” components. This bias risk is heightened when dealing with proprietary supplier information, which is often released selectively.

True production capacity, yield rates, and quality-control pass rates for low-CTE fibreglass remain undisclosed due to competitive sensitivity. Public sources offer only partial proxies, such as shipment estimates or customer contract counts, limiting the depth of quantitative modelling. Without these specifics, risk estimates inevitably rely on assumptions that may not hold under operational stress.

Metrics vary significantly between datasets. For example, Susquehanna’s semiconductor lead-time index measures order-to-delivery timelines for chips, which may not directly map to fibreglass cloth. Similarly, IDC and Statista may classify suppliers differently when reporting market shares, leading to distortions when cross-referencing figures.

Some observed relationships, such as the link between supply concentration and delayed product launches, are supported by historical patterns but cannot be definitively proven as causal in the present case. Other factors, including downstream assembly capacity or parallel component shortages, may drive or exacerbate delays independently of the low-CTE material issue.

Taken together, these limitations narrow the confidence intervals around both the timing and scale of the projected impacts. They also highlight that while the risk of disruption is clear, its precise magnitude is uncertain.

Recommendations and Conclusion: Business Project of Apple

Recommendations:

The preceding evaluation has shown that Apple’s vulnerability in the low-CTE fibreglass shortage is not an isolated operational issue but a structural weakness in its supply chain design. The company’s dependence on a single specialist supplier, Grace Fabric Technology, magnifies geopolitical, economic, and operational risks.

In light of this, the recommendations below aim to address both the urgent pressures threatening the iPhone 17 launch and the longer-term systemic fragilities. Each is grounded in the earlier analysis and subjected to a critical assessment of feasibility, potential trade-offs, and competitive positioning.

In the short term, Apple must lock in priority production with Grace while qualifying at least one backup supplier. Securing production now is vital because supplier power, as seen in Porter’s Five Forces, is at its peak.

Early commitments, possibly backed by financial incentives, can guarantee the bare minimum volumes to protect the iPhone 17 launch. But this comes with a trap: it could lock Apple into high prices and deepen the dependency already flagged in the SWOT.

That is why a diversification push must start now. Even a partial second source creates breathing room and sends a signal to markets that Apple is reducing its single-point risk. The challenge is quality control; any slip in standards could hit brand trust hard.

Over the long term, Apple should invest in in-house production capability for critical materials, either through direct manufacturing or joint ventures with established suppliers in multiple regions. Vertical integration, as seen in Samsung’s component divisions, has proven to mitigate supply risk by securing both technical know-how and production control. For Apple, this move would offer greater resilience and bargaining power, insulating it from geopolitical disruptions and market shortages.

Yet the barriers are considerable: capital expenditure would run into billions, lead times for plant construction and certification could span several product cycles, and the company would face a steep learning curve in a material science domain where it currently lacks deep expertise.

Moreover, the economic analysis earlier suggested that inflationary pressures and volatile exchange rates could inflate project costs beyond initial estimates. Therefore, while the strategic case is compelling, execution risk is high, and the benefits may not materialise until after multiple product generations.

Alongside this, Apple should set up long-term, multi-region partnerships with a handful of key suppliers. These should go beyond simple purchase contracts to shared R&D and joint investment in production capacity.

This could give Apple early access to new materials and a more stable supply, but competitors like Huawei and Samsung already have a head start, which may limit Apple’s leverage.

Customer-facing measures are also essential. If delays are unavoidable, Apple should be transparent with customers and offer incentives, priority upgrades or extended AppleCare, to keep loyalty intact. The social risk in the PESTLE analysis made clear that unmet expectations can damage brand equity quickly. The danger is that over-sharing could trigger investor anxiety, so messages must balance honesty with confidence.

These actions mix fast fixes with structural reforms. But they will only work if Apple executes with speed, invests consistently, and adapts its internal culture to value supply chain resilience as much as product design.

Conclusion:

The low-CTE fibreglass shortage confronting Apple is more than a temporary supply disruption; it is a case study in how single-source dependency intersects with geopolitical, economic, and operational vulnerabilities.

The purpose of this report was to evaluate the scale and nature of this challenge and to present strategic options for mitigating immediate impacts while building long-term resilience. Drawing on PESTLE, Porter’s Five Forces, SWOT analysis, and a data-driven evaluation of revenue exposure, operational delays, and supplier concentration, the findings are unequivocal: concentrated revenue streams combined with concentrated supply create disproportionate strategic risk.

The data showed the iPhone brings in about 50% of Apple’s revenue. Even a one-month launch delay could mean billions in deferred sales. Supplier mapping confirmed that only a handful of producers can meet Apple’s needs, giving them the power to set terms. Competitors with diversified supply chains are better placed to keep launches on track during disruptions.

The recommended strategy is twofold: deal with the immediate supply squeeze through urgent negotiation and quick diversification, and build long-term resilience through vertical integration, strategic partnerships, and stronger supplier management. Customer-facing steps help protect brand equity during disruption, but cannot replace operational solutions.

The main strength of this plan is that it addresses both immediate and long-term risks. Securing priority supply now protects the iPhone 17 launch, while diversification and investment in production build resilience for the future. The weakness is that these measures are costly, slow to deliver, and face real limits in such a specialised market. Even with action, Apple may never fully remove single-point risk for materials in this niche.

In conclusion, the shortage exposes a structural fragility in Apple’s otherwise formidable operational model. The strategic value of this report lies not only in its specific recommendations but in framing supply chain resilience as a core competitive capability rather than a reactive fix. For Apple and the broader technology sector, the lesson is clear: in an era of geopolitical volatility and hyper-specialised components, resilience must be designed into the supply chain from the outset, not bolted on after a crisis emerges.