Operations and Service Management of Unilever

The report “Operations and Service Management of Unilever”, focuses on how the Unilever Public Limited Company, the biggest firm worldwide, makes its everyday products and manages all its operations. Unilever is a huge multinational firm that is known for producing a wide variety of products that people can use in their regular activities. These items refer to the drinks, foods, and cleaning with the personal care products.

Unilever is a socially responsible firm because it constantly works on improving its processes and key products. The firm puts various efforts input the entire innovations, which refers the developing new ideas and finding better ways of doing things.

The report looks at how Unilever manages the quality within the manufacturing process. Quality management is an important tool that helps Unilever maintain a better reputation and generate happiness for its customers. The report will explain the current ways Unilever manages quality, suggesting better and possible improvements with the discussion of how advanced technologies can improve business-related activities.

Read more: Advanced Project Management of Unilever

Overview of Unilever and Its Selected Operational Management Practices:

Overview:

Unilever Public Limited Company, has a long history that began almost one hundred years ago. The firm was created in 1929 and was formed by the Dutch Company and the British Company. Unilever has grown its activities and manages the different countries’ operators with many products. The firm owns a variety of well-known brands that support the activities of millions of people with the use of daily activities.

The firm owns a variety of well-known brands that process the activities of millions of people. Unilever’s main office and headquarters are located in England. The firm’s shares are also traded on the stock markets in various countries, which enables the company to address the business’s investment terms.

Focused Operations and Management Practices:

Unilever pays close attention to quality management because it refers to the systems, efforts, and key procedures that the firm puts in place to analyze whether the products are made with higher standards and meet the overall expectations of customers.

Quality Management refers to the products and determines the business’s roles, follows the rules, and proceeds according to the regulations by addressing the incisura-based organizations. Quality management is the broad process that refers to the various important parts, such as consistent product formulation, hygiene and safety standards, and Supply Quality Checks.

Unilever does not make any sense that affects the business values, its overall resources, and the business funding. Unilever produces various products that are used on the body and for food. The firm keeps all the precuts, such as being Clean and Hygienic, which are effective for raising the overall brand value. Listening to the customers is a big part of the quality management at the Unilever firm.

The firm collects and reviews the feedback from the people who buy and use the advanced products. This term helps to understand what customers like or dislike about the quick fixing of the key issues.

Theoretical Background:

Six Sigma:

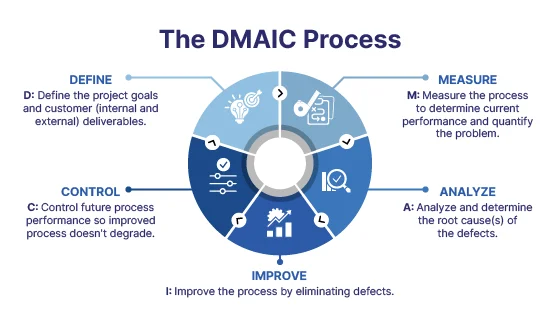

Six Sigma is the technique that focuses on making the processes more efficient and decreasing eh number of errors in the products. The term Six Sigma comes from various statistics and measures the variations as well as errors that exist in the process part, The aim is to have fewer than 3.4 defects and get opportunities as high as possible and quality.

Define:

Unilever Inc. would identify the issue and the process that needs improvement. For Instance, the firm’s Soap Products sometimes have an inconsistent level of fragrance. Unilever’s quality team would define the issue that needs to be fixed.

Measure:

Unilever’s quality management team collects data about the current processes that understand how defects occur. Unilever might evaluate how many soap bars don’t fulfill the standards of fragrance.

Analyze:

Unilever’s quality management team analyzes the current process with the root causes. The variation appears due to the Inconsistent Fragrance Oil that is sourced from the suppliers at local and international markets.

Improve:

Unilever would execute the changes to the process that decrease the defects. This term could refer to changing the suppliers, the machine settings, and improving the workers’ training,

Control:

Lastly, Unilever’s quality management team establishes the controls to keep the process stable and prevent the defect from returning. This term might involve regular quality checks and automating the sensors in the entire production line.

Total Quality Management:

TQM- Total Quality Management is a broader, as well as holistic, approach to managing the overall quality. TQM refers to the entire firm that works together to raise the quality of each element and part of the firm. Quality is not only the main element of a quality control team, but the team is also responsible for meeting as well as exceeding the expectations of the customers.

Customer Satisfaction:

Unilever’s total quality management refers to the goals that make the customers happy. Unilever sees the feedback from various customers and understands their needs and expectations. This technique helps the firm to decide the products that raise the trust of the customers,

Employee Involvement:

Total Quality Management encourages all employees to participate in quality improvements. For Instance, the workers in a factory on the production line might Identify Small Defects before they become major defects and suggest possible solutions. Unilever always supports the training and empowers employees to take ownership to determine their business roles.

Continuous Improvement:

Total Quality Management is about never stopping the key efforts to improve the review of the process and generate feedback to find better ways to do better. Unilever’s quality management team must develop continuous implementation that enhances the business preferences builds the cleared values and generates a higher level of strength that allows to initiate the business roles.

Alternative Techniques in Use or Application at Unilever:

The traditional quality management methods are not enough to generate a higher level of success and manage business growth. There are a lot of techniques that can be used by Unilever to improve its production capacity and generate overall preferences that might be useful in the future.

Capacity Management:

Capacity management indicates the ability of the firm to analyze how much it produces based on the total demand. Unilever has the clear flexibility to shift production among the various regions depending on where the demand is higher and where the capacity is available.

For Instance, if the demand for the key product increases in Asia, Unilever might increase production in factories there or move some production from Europe to meet the demand. The downside of sight production is that the quality can vary, and the control system and lead to harmful reputations.

Moreover, capacity management techniques are useful for meeting the demand and carefully balancing the strict quality control that prevents variations in the core final products.

Supply Chain Management:

Unilever’s supply chain is very vast a complex involving thousands of suppliers across the world. The management of the supply chain is a huge task. Unilever can maintain product quality by Performing Strict Audit Assessments. The audit checks whether suppliers fulfill Unilever’s standards for quality checks and ethical sourcing.

Unilever will visit supplier factories to review their process and ensure the follow-up manualizing roles. There are still changes, especially with the smaller suppliers located in rural areas. Unilever continuously works to strengthen the changes and meet the overall specific roles that are analyzed to determine the business values.

Quality Management Through Entire Automation:

Unilever Public Limited Company has invested in various automation techniques to improve quality management. Automation inspection tools like Sensors, Cameras, and the Software System that is used to control the production lines and detect defects with the quality standards in real-time. Automaton helps to reduce human errors, speeds up inspections, and allows the firm to respond quickly if problems are detected.

Automation is widely used in factories, then it is then developed to proceed with less common developments. The automated quality control tools in all the production sites help to raise consistency and reduce the total errors.

Integration of Digital Technology in Quality Management at Unilever Corporation:

Digital technology plays a vital role in helping firms such as Unilever maintain as well as improve the quality of their production. Digital Technology brings a new level of precious and speed, which the traditional manual processes can’t match. Unilever can better monitor the production and detect the issues, respond quickly to ensure the product is extremely, and maintain the changes. Artificial Intelligence and Robotic Process Automation are the main technologies that are used by Unilever to generate suitable activities,

Artificial Intelligence:

AI- Artificial Intelligence is the kind of computer technology that is designed to mimic human roles but with a higher accuracy level. An AI system can evaluate a wider range of production data in real time, which means that it can look at each detail of the manufacturing process. The capability will allow AI to explore the defects and notify humans of the entire change. For Instance, AI-Powered Image Recognition Tools can help to build an effective prediction line and reduce errors, like damaged seals and misalignment of the production.

Artificial Intelligence also has the clear ability to predict the machinery as well as equipment’s might need to be maintained to prevent breakdowns. Artificial Intelligence can forecast potential failures and recommend the time to disrupt the change. AI can suggest the process by continuously analyzing the data trend and help Unilever optimize the manufacturing operations to produce better products effectively.

Robotic Process Automation:

Robotic process automation refers to the software tools that can automate repetitive and rule-based tasks that humans typically do. Various round activities like data entry, combining the reports, and tracking the test results. For Instance, Robotic Process Automation can take over specific tasks by working tirelessly and the consistent accuracy.

Robotic Process Automation can gather the data and manage the various sources with the compilation of compliance reports to track the product test results over a specific time. Unilever’s employees are directly encouraged to focus on higher-value activities and generate the proper quality assurance roles.

Benefits of Digital Technology Integration:

- Unilever can enhance accuracy with the use of Artificial Intelligence Quality Inspection Tools that can detect defects and variations. This term increases customer satisfaction and ensures continuous production.

- Unilever can set up the digital system, like investments in the long run, and decrease the need for manual inspection. So, the company can manage the overall cost, which helps to increase the performance and generate a higher level of financial analysis.

Drawbacks of Digital Technology Integration:

- The execution of Artificial Intelligence and Robotics Process Automation in quality management required investments in software and hardware. Unilever must develop substantial financial commitments to implement these digital integrated technologies to raise the business strengths.

- Automation often raises issues about the key potential job losses in the management of manual tasks. Unilever must build careful reskilling programs for employees, here creativity is an important element to ensure the technology is complemented as compared than replacing the human workers.

Supporting Functions and Role in Unilever’s Quality Management Actions:

Unilever’s quality management system is not dependent on the manufacturing or quality control team. It relies heavily on the corporations and the collaboration of various departments across the firm. Finance, Operations, HRM, and other key departments directly support the business to achieve the business values.

Finance:

Unilever’s financial professionals assess the cost-benefit ratio of the improvement of quality projects. The finance department of Unilever is carefully analyzing the executed ROI- Return on Investment. For Instance, Unilever executes the expense AI-driven inspection system and analyzes the proper cost control activities. Unilever can balance the short-term costs with the long-term advantages, with the firm to sustain the brand reputation in the global market.

Operations:

The operations team is the heart of Unilever’s quality management strides. These teams are liable for putting the quality assurance plans into real-time actions on the production line for each data point. The operational team coordinates with the quality control specialists to identify the root causes and execute the corrective actions. Operations personnel also ensure automated quality inspection tools, like AI-powered cameras and robotic sensors.

Marketing:

Unilever’s marketing team has a unique but critical role in supporting quality management. The firm gathers value feedback and manages the customers through various surveys and social media to conduct market research. Product freshness and environmental impact are also analyzed by the marketing department of Unilever Inc.

This department is responsible for promoting all the products of the business across the globe by using both offline as well as online media that initiate accessibility and reach a wider audience of Unilever.

HR- Human Resources:

The Human Resource department is another supporting function that contributes to Unilever’s quality management success. Quality management is about the processes and key tools that depend on people. HR’s key roles are designing and delivering the training program that reaches the employee with proper quality procedures.

HR supports the initiatives of talent development and focuses on building advanced initiative skills among the workforce. Unilever’s Human Resource management team is responsible for building specific motivation and specific among the workers by offering financial and non-financial incentives, providing career opportunities, and ensuring a work-life balance.

Recommendations for Improvement:

- Unilever Inc. should implement the lean management principle to streamline the processes and eliminate waste. One of the effective ways that Unilever adapted to improve quality management is the wider application of Lean Management Principles. Unilever applies the lean principles to carefully analyze the mapping of the entire reproduction process from the raw materials.

- Unilever should enhance supplier relationship management for better quality and collaboration on raw materials. Supplier relationship management refers to the building of collaborative and long-term relationships with the suppliers, such as trading with transactional vendors. Unilever can organize workshops and share key knowledge with the help of smaller suppliers that ignite effective roles and create better eras of success.

- Unilever Inc. should expand the use of digital technologies to enhance quality controls. AI-powered systems can be integrated into the production lines to improve the real-time performance and detect the number of errors that affect the business performance, Moreover, Robotic Process automation offers various opportunities to automate the repetitive administrative tasks that require manual efforts.

Conclusion: Operations and Service Management of Unilever

Unilever Public Limited Company has a strong foundation in quality management and is supported by the global process and systems. Moreover, the firm can improve the embracing modern operations and digital technologies. Lean management and Supplier Relationship Management can decrease waste and improve collaboration with the supplier.

Multiple departments like finance, HRM, supply chain, operations, and others are responsible for performing the business activities and overall related actions. Unilever can fulfill higher standards in quality by maintaining its position in the global consumer goods industry with the use of automated technologies. Customer feedback can come from various surveys and social media activities that enhance customer service and generate product reviews.

Unilever does not make everything itself and relies on various suppliers to offer raw materials like oil and flavors, along with other ingredients. The company checks these suppliers and ensures the materials are provided to meet the quality standards. This term involved the regular inspections and testing of the key materials the working closely with suppliers to solve any type of issues.